Microporous metal ceramic insulation is an advanced material designed for high-performance thermal insulation applications. This type of insulation combines the properties of metal and ceramic with a microporous structure, resulting in excellent thermal resistance, low thermal conductivity, and high-temperature stability.

Microporous metal ceramic insulation Manufacturing Processes

Sintering:

The mixture of metal and ceramic powders is sintered at high temperatures to create a dense, interconnected microporous structure.

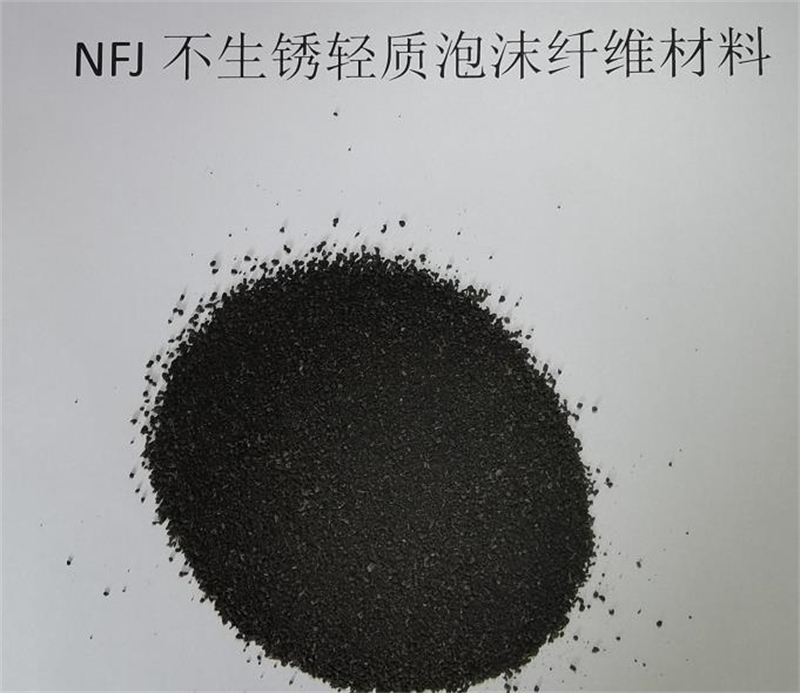

Foaming:

Metal and ceramic materials can be mixed with foaming agents that create a porous structure during the manufacturing process.

Chemical Vapor Deposition (CVD):

A process where metal and ceramic components are deposited from the vapor phase to form a microporous layer on a substrate.

Extrusion and Molding:

Techniques that allow shaping the material into various forms suitable for different applications.