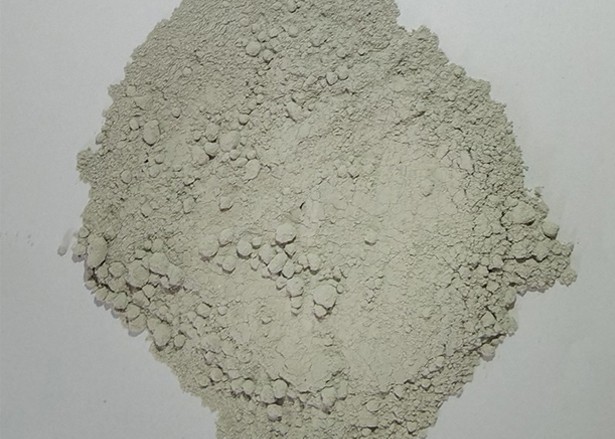

Ultrafine iron powder, characterized by its extremely small particle size typically below 100 nanometers, plays a pivotal role in various industrial applications due to its unique properties and behaviors. These powders are produced through advanced techniques such as gas atomization, mechanochemical processes, or reduction of iron oxides. The creation of ultrafine particles enhances the surface area-to-volume ratio significantly, which in turn alters the magnetic, chemical, and mechanical properties of the material.

One significant aspect of ultrafine iron powder is its application in the manufacturing of sintered components. Due to its fine particle size, it allows for improved densification during the compaction process, leading to components with enhanced mechanical strength and durability. Industries such as automotive and electronics leverage these advantages to produce high-performance parts that exhibit superior wear resistance, reduced friction, and enhanced conductivity.

In the realm of magnetics, ultrafine iron powder is often utilized in the production of high-performance magnetic materials. When incorporated into magnetic composites, these powders improve magnetic saturation and allow for the development of more compact and efficient electromagnets. Additionally, their unique properties are harnessed in the creation of high-frequency inductors and transformers, where efficiency is paramount.

Furthermore, ultrafine iron powder finds its applications in catalysis and environmental remediation. Its high surface area improves reaction kinetics in catalytic processes, making it an essential component in petrochemical and chemical synthesis. More recently, researchers are exploring its potential in addressing environmental challenges by employing it in the reduction of pollutants and contaminants in soil and water.

The advancements in nanotechnology have also led to the exploration of ultrafine iron powders in medicine, particularly in targeted drug delivery systems and magnetic resonance imaging (MRI). The biocompatibility and magnetic properties of these powders hold promise for enhancing the efficacy of treatments while minimizing side effects.

With the ongoing research into the diverse applications of ultrafine iron powder, it is vital to consider both the opportunities and challenges in adapting these materials for specific uses. Emerging technologies and methods to produce and manipulate ultrafine powders will continue to expand their applications, leading to significant implications across numerous sectors.

In summary, ultrafine iron powder is a versatile material with a range of applications spanning various industries. Its unique properties derived from its nano-sized particles make it an essential component in the development of advanced materials and technologies, reflecting its ongoing importance in modern industrial practices.

Show More >>

PRODUCTS

You are welcome to contact us at any time, please write the message here and we will reply you in 24 houre. thanks foryour support.