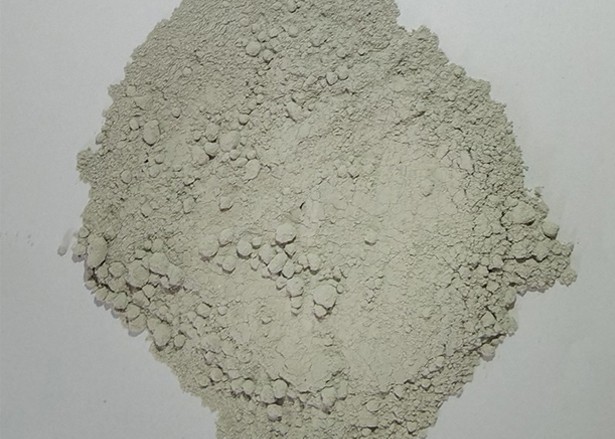

Iron powder for chemical synthesis is a versatile material widely utilized in various chemical processes, owing to its unique properties and high reactivity. As a fine particulate form of iron, this powder serves as a catalyst and a reducing agent in several reactions, making it invaluable in fields such as organic chemistry, metallurgy, and materials science. Its use is well-established in industries ranging from pharmaceuticals to energy generation, underlining its significance in advancing chemical synthesis techniques.

The essential characteristics of iron powder make it particularly effective for these applications. With a high surface area-to-volume ratio, iron powder facilitates rapid reactions and enhances the efficiency of catalytic processes. Its reactivity varies based on particle size, morphology, and purity, allowing researchers and engineers to tailor it to specific chemical reactions. In the synthesis of complex organic molecules, for example, iron powder can effectively facilitate reductions, offering an environmentally friendly alternative to more toxic reagents.

Historically, iron has been known for its utility in metallurgy and as a binding agent. However, the growing emphasis on sustainable practices within the chemical industry has led to a renewed interest in its usage. Iron powder is recognized as a safer and more cost-effective alternative to precious metals, thus playing a crucial role in green chemistry initiatives. Furthermore, its natural abundance and low environmental impact align with the industry's shift towards sustainable development.

Experts in the field have extensively researched and documented the various applications of iron powder in chemical synthesis, showcasing its pivotal role in innovative formulations and advancements. Studies highlight its effectiveness in creating organometallic compounds, performing reductions, and as a placeholder for more hazardous materials. With ongoing research, the applications of iron powder continue to expand, showcasing its versatility and adaptability in synthesis.

Moreover, the production of high-purity iron powder has seen vast improvements, allowing for consistent quality that meets industrial standards. Its manufacturing processes include atomization, reduction, and milling techniques, optimizing for specific characteristics needed in diverse applications.

In conclusion, iron powder represents a critical component in chemical synthesis, marked by its unique properties, environmental benefits, and wide-ranging applications. As industries pursue greener solutions and more efficient processes, the demand for iron powder is likely to grow, solidifying its reputation as an essential agent in modern chemistry. This alignment of expert knowledge, practical application, and sustainable practices underscores the increasing importance of iron powder in advancing chemical synthesis methodologies.

Show More >>

PRODUCTS

You are welcome to contact us at any time, please write the message here and we will reply you in 24 houre. thanks foryour support.