## Understanding Iron Powder for Magnetic Applications

Iron powder has emerged as a crucial component in various magnetic applications, thanks to its unique properties, cost-effectiveness, and superior performance. The key to its functionality lies in its physical and chemical characteristics. Primarily, iron powder possesses high permeability, allowing it to effectively channel magnetic fields, making it an essential material for electromagnets, inductors, and transformers.

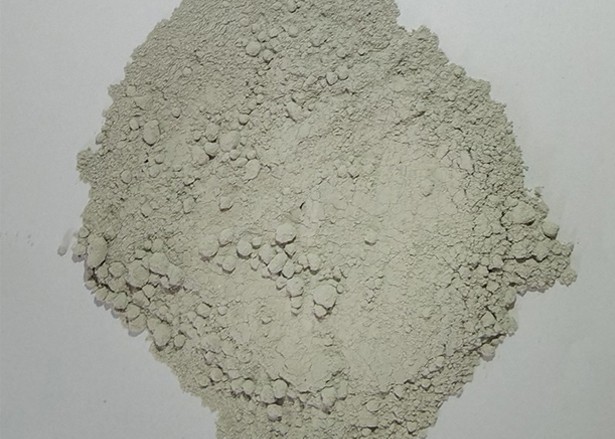

Iron powder is produced through various methods including atomization, reduction, and milling. The particle size and morphology of the iron powder significantly affect its magnetic performance. For instance, fine particles provide a larger surface area, enhancing magnetic saturation and reducing energy losses during operation. Modern advancements in technology have made it possible to control these variables meticulously, leading to greater precision in magnetic applications.

One significant application of iron powder is in soft magnetic composites (SMCs). SMCs are made by compacting the iron powder with insulating binders, which allows better performance in electronic components. By employing advanced processing techniques like spark plasma sintering, manufacturers can achieve a higher density while retaining the soft magnetic properties, making these composites ideal for use in electric motors and power supplies. This strategic use of technology results in lighter, more efficient, and sustainable energy sources.

Furthermore, iron powder finds utility in automotive applications, particularly in electric vehicle (EV) technology. The lightweight and strength properties of iron powder allow for the production of efficient electrical components, including rotors and stators. For example, in the production of electric vehicle motors, iron powder is used in the rotor design to enhance magnetic efficiency and reduce heat generation, thereby improving overall vehicle performance.

In conclusion, iron powder for magnetic applications functions through advanced material properties that allow it to effectively channel and interact with magnetic fields. The production methods leverage modern technologies to ensure efficiency, minimizing waste while improving quality. As manufacturing processes continue to evolve, the importance of high-quality iron powder will only grow, particularly in the context of energy-efficient solutions. For innovative applications and sourcing of iron powder, directly reach out to reputable suppliers. Should you have any inquiries, do not hesitate to contact us for more information.

Show More >>

PRODUCTS

You are welcome to contact us at any time, please write the message here and we will reply you in 24 houre. thanks foryour support.