## Activated Iron Powder for Wastewater Treatment: How It Works

Activated iron powder has emerged as a revolutionary solution in wastewater treatment, primarily due to its remarkable ability to remove contaminants such as heavy metals, phosphorus, and organic pollutants. This article delves into the intricate working mechanisms of activated iron powder, highlighting its key components, advanced technologies employed in its production, and its significance in modern manufacturing.

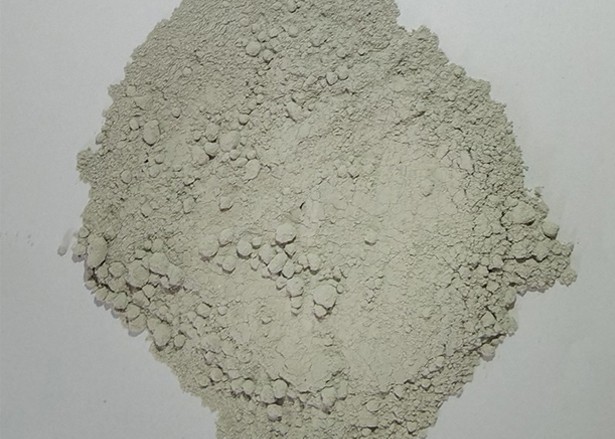

At the core of activated iron powder’s effectiveness are its unique physical and chemical properties. The activation process involves the reduction of iron oxides through various means, which results in a high surface area, increased porosity, and enhanced reactivity. This transformation allows the iron powder to engage actively with pollutants in wastewater, facilitating a series of chemical reactions that lead to contaminant removal.

One important mechanism is adsorption. Activated iron powder operates through a process where contaminants in the water phase are attracted to and held on the surface of the iron particles. This efficient adsorption process reduces the concentration of harmful substances effectively. Simultaneously, reduction reactions occur, where metal ions, such as lead and chromium, are converted into less hazardous forms and immobilized, rendering them safer for disposal.

Advanced technology plays a crucial role in the efficient production of activated iron powder. Techniques such as mechanochemical activation — involving grinding iron powder under specific conditions to enhance its properties — ensure consistent quality and reactivity. Innovations in particle size distribution control further enable the customization of the activated iron powder for various wastewater applications, optimizing it for different types of contaminants.

Practical application scenarios illuminate the prowess of activated iron powder in real-world settings. For example, in industrial metal finishing processes, activated iron powder can effectively remove hexavalent chromium from wastewater, a toxic compound often found in electroplating effluent. In municipal wastewater treatment, it assists in the reduction of organic pollutants and enhances the treatment efficiency of existing systems, thus supporting regulatory compliance.

In conclusion, the integration of activated iron powder into wastewater treatment processes exemplifies a modern approach to tackling environmental challenges. By leveraging advanced technology for efficient and scalable production, activated iron powder not only provides a reliable solution for contaminant removal but also signifies progress in sustainable manufacturing practices. For those interested in optimizing their wastewater treatment solutions, contact us to learn more about reliable suppliers offering high-quality activated iron powder.

Show More >>

PRODUCTS

You are welcome to contact us at any time, please write the message here and we will reply you in 24 houre. thanks foryour support.