- +86 18501963811/+86 17600532308

- beijingjinke@163.com

Groundwater pollution has become an important environmental problem in the world, and the restoration of groundwater has become a top priority in the environmental protection field. PRB technology (permeable reactive grid) can effectively remove pollutants such as heavy metals and organic substances. At present, PRB technology is gradually replacing the extraction treatment technology with high operation cost and becoming the new development direction of groundwater remediation.

Product Description

PRB (Permeable Reactive Barrier) is a remediation technology used to treat contaminated groundwater by allowing it to pass through a reactive medium that removes pollutants. The materials used in a PRB serve to filter and treat contaminants, often through chemical, biological, or physical processes.

At present, PRB technology is gradually replacing the extraction treatment technology with high operation cost and becoming the new development direction of groundwater remediation. However, the selection of PRB reaction medium is particularly important. Currently, the commonly used filling medium has the disadvantages of small specific surface area, low pore gland rate, easy caking, mostly removing only a single pollutant, low removal rate for multiphase pollutants, etc., which seriously affects the water treatment effect and limits the application of PRB technology. Therefore, Beijing jinke composition materials co., ltd. developed NFJ-PRB filling medium materials, this new material is a kind of filling medium with high efficiency, low consumption, low price, and comprehensive physicochemical and biochemical treatment of pollutants, greatly improving the repair ability of PRB.

Application Scope

PRB technology refers to the construction of a metal active material wall underground to form a passive reaction zone to intercept sewage. Sewage reacts through the wall by natural hydraulic transmission, and harmful substances therein are degraded, adsorbed, precipitated and removed.

NFJ-PRB filling medium takes ferrous porous materials as the main raw materials, and takes advantage of the characteristics of active metal chemical properties and the formation of various forms of aqueous compounds in natural state to play the roles of electrochemical enrichment, coagulation and adsorption. Under the action of sedimentation, flocculation and adsorption, the remediation effect of PRB technology on groundwater can be greatly enhanced. More importantly, NFJ-PRB filling medium can provide sufficient space for the enrichment and growth of microorganisms, and provide a good "microenvironment" for the synergistic symbiosis of various aerobic, facultative and anaerobic microorganisms in the biochemical reactor. This realizes the comprehensive treatment of pollutants by physico-chemical and biochemical methods.

Primary Application:

Chlorinated Solvents: ZVI is highly effective at reducing chlorinated solvents such as trichloroethylene (TCE), perchloroethylene (PCE), and other volatile organic compounds (VOCs). ZVI reduces these pollutants through a process called reductive dechlorination.

Heavy Metals: ZVI also reduces metals like chromium(VI) (to chromium(III)) and arsenic in contaminated groundwater.

Hydrocarbons: Effective for treating some petroleum hydrocarbons like BTEX (benzene, toluene, ethylbenzene, xylene).

Application Benefits:

Long history of successful use for halogenated hydrocarbons.

Can treat a wide variety of contaminants, including organic and inorganic pollutants.

Provides a relatively fast and effective means of groundwater remediation.

Primary Application:

Organic Contaminants: Activated carbon is widely used for the adsorption of organic contaminants such as petroleum products, solvents, pesticides, and other industrial chemicals. It is also effective in adsorbing chlorinated compounds, VOC, and polyaromatic hydrocarbons (PAHs).

Water Treatment: Activated carbon is often used in groundwater treatment for both VOCs and other dissolved organic compounds.

Application Benefits:

High surface area for adsorbing organic contaminants.

Efficient in removing a broad spectrum of contaminants.

Can be regenerated or replaced depending on the contaminant load.

Primary Application:

Petroleum Hydrocarbons: Organic material such as wood chips and compost support microbial communities that degrade hydrocarbons through biodegradation.

Chlorinated Solvents: These materials can support anaerobic microorganisms that reduce chlorinated solvents (such as TCE or PCE) via reductive dechlorination.

Nitrate and Ammonium Contamination: Bioreactors with organic matter can also treat nitrates and ammonium through microbial processes.

Application Benefits:

Eco-friendly, low-cost, and natural materials.

Can treat a variety of contaminants, including petroleum products and chlorinated solvents.

Enhances bioremediation, promoting microbial breakdown of contaminants.

Primary Application:

Heavy Metals: Limestone and calcite are effective in treating contaminants like lead, cadmium, zinc, and other metals through a process called precipitation.

Acidic Groundwater: These materials can neutralize acidic groundwater by raising the pH, which can help with the immobilization of metals and reduce toxicity.

Radionuclides: Limestone has been used in some systems to immobilize certain radionuclides in groundwater.

Application Benefits:

Cost-effective and readily available.

Effective for metal immobilization and treating acidic groundwater.

Primary Application:

Heavy Metals: Zeolite is a highly porous material that is effective for adsorbing metals like lead, cadmium, zinc, and ammonium ions.

Radionuclides: Certain types of zeolite are used to treat radionuclides.

Hydrocarbons: Zeolite can also adsorb hydrocarbons and VOC, although it is less effective than activated carbon.

Application Benefits:

High ion-exchange capacity.

Effective in a wide range of applications, including heavy metal removal and ammonium adsorption.

Can be regenerated and reused in many cases.

Primary Application:

Heavy Metal Immobilization: Phosphate-based materials, such as apatite, are effective for removing heavy metals such as lead, cadmium, and zinc by forming insoluble phosphate precipitates.

Contaminated Groundwater: Phosphate minerals can be used to treat groundwater contaminated with metals by precipitating them in a form that is immobile and non-toxic.

Application Benefits:

Long-lasting and highly effective for immobilizing metals.

Provides permanent removal of certain metals from the water.

Low-maintenance once installed.

Primary Application:

Flow Management: Sand and gravel are primarily used as a physical barrier to control the flow of groundwater and to support other reactive materials. They are often used as structural media within the PRB.

Coarse Filtration: Sand and gravel can also help to filter out larger particles and prevent clogging of reactive materials.

Application Benefits:

Cost-effective, widely available, and easy to install.

Helps maintain the structural integrity of the barrier and supports other reactive materials.

Primary Application:

Complexation of Organic and Inorganic Contaminants: Synthetic polymers or natural polymers like chitosan can be used to complex or absorb contaminants, including metals, hydrocarbons, and organic solvents.

Radionuclide Removal: Some polymers are designed to treat radioactive contaminants.

Application Benefits:

Tailored for specific contaminants.

Easy to handle and install.

Can be combined with other materials for enhanced remediation.

Advantages And Features

1. A filling medium with high efficiency, low consumption, low price and comprehensive physicochemical and biochemical treatment of pollutants;

At present, most PRB technologies use the mixture of iron powder, activated carbon, zeolite and quartz sand as the reaction medium. These combinations are not only costly to use, but also easy to fail, such as zeolite. NFJ-PRB filling medium only needs to be filled separately due to its special structure which can simultaneously perform both physicochemical and biochemical functions.

2. No secondary pollution will be generated

Iron powder is easier to carry out oxidation-reduction reaction under alkaline conditions, causing more precipitation in the reactor and causing reactor blockage; Aluminum powder is easy to passivation, and the PH value of the reaction system needs to be accurately controlled. In addition, aluminum salt may damage human brain. NFJ-PRB filling medium can form a large number of primary cells due to its special chemical composition, which can effectively reduce harmful pollutants without passivation and blockage.

3. The activity is kept for a long time, the treatment function can be effectively exerted for a long time, and the cost problem caused by replacing the filling medium is greatly reduced.

4. Uniform particle size and easy construction.

| PhysicalIndex | Density(g/cm3) | Bulk Density(g/cm3) | Particle Size(mm) | Appearance |

| 2.3~2.7 | 1.7~1.88 | 0.5~5.0 | Gray and black have bright spots.、Loose sponginess |

Application Effect

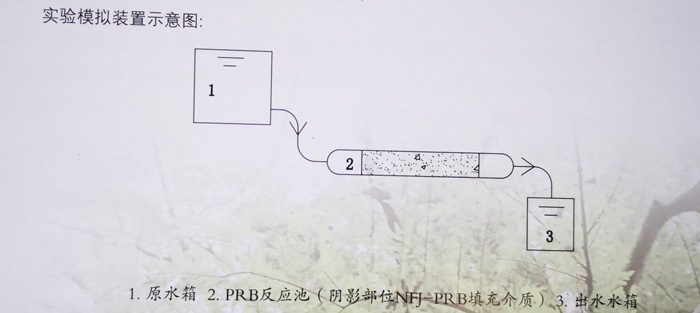

Lanzhou Jiaotong University successfully removed some metals and organics from groundwater through an experimental simulation device. The experimental water contains higher copper (> 10 mg/l) and some organic substances such as 1, 2 dichloroethane.

The concentration of copper was less than 0.01mg/L and the concentration of 1,2 dichloroethane reached the corresponding standard by using PRB technology and filling NFJ-PRB medium through continuous reaction.

02 2nd Floor, No.1 Building, Longzeyuan Complex Building, Huilongguan Town, Changping District, Beijing, PR.China

+86 18501963811/+86 17600532308